Posted in: Temperature Control

Got temperature control questions? We've got answers! We've rounded up our customers' most frequently asked temperature control questions, and addressed them below to help you start the year off with some helpful tips.

| Why is the temperature control of engine fluids important? | |

| Controlling the temperature of engine fluids is essential to ensuring equipment efficiency and performance. Depending on the application, failure to maintain temperature accuracy can lead to poor fuel consumption, high emission output, long warm-up times, unnecessary wear-and-tear on the engine, and smoking. |  |

| How can I tell if my thermostatic valve needs maintenance? | |

| Some common signs that your valve needs maintenance include longer than normal warm-up times, slow temperature response, white smoke, or excessive emissions. The ability of your temperature control valve to maintain a constant temperature can change over time and, therefore, should be included in your preventative maintenance and service schedules to ensure accuracy. This blog article explains how to clean and inspect a thermostatic valve, and our recommendations for valve maintenance. | |

| How can I prevent valve stem leakage in a high vibration application? | |

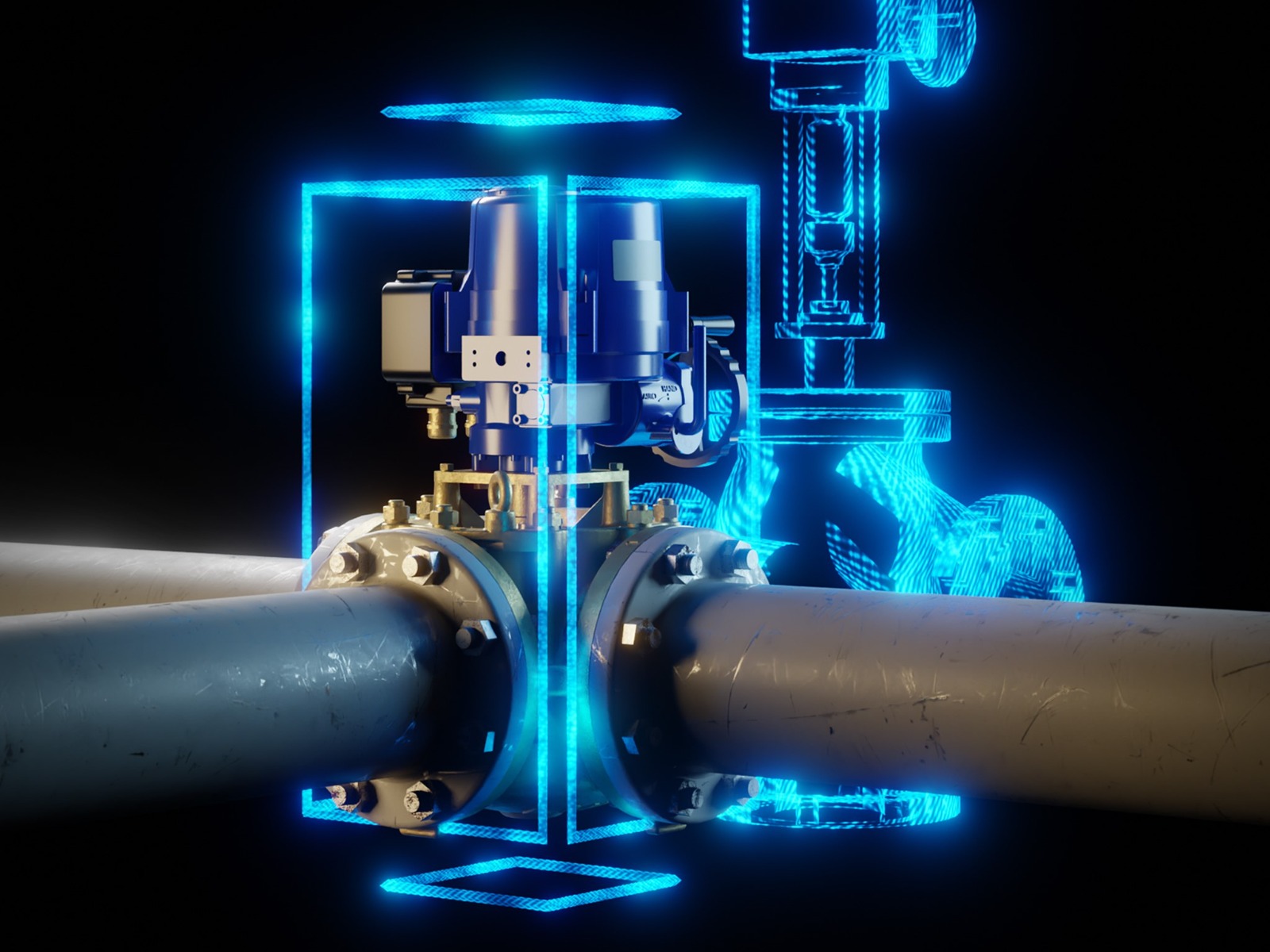

| High vibration environments often cause stem damage and coolant leakage in globe-style valves. The AMOT rotary-style G valve’s durable actuator, combined with its compact design, is engineered to withstand vibration and resist damage. Watch this video to learn more. |  |

| Do I need a special element for my application? |  |

| Standard bronze and steel elements work well in almost all applications. However, if your application contains corrosive fluids, such as ammonia or salt water, we recommend electroless nickel plated elements for protection. | |

| What do the numbers mean on my AMOT valve? | |

| When you look at the nameplate of any AMOT product, the numbers may seem random, but they actually correspond to a specific attribute of that valve. In fact, if you have a complete model number, we can tell you exactly what type of valve you have, the temperature set point and any unique characteristics that were added to the build. If you would like to know exactly what each number means, you can refer to the product's data sheet, or give us a call for help. |  |

| What information do I need to specify a thermostatic control valve (TCV)? | |

| To narrow down the best valve family for your application, at minimum you would need to know the process information including fluid type, flow rate, pressure, and temperature range with design operating temperature. To complete the selection and obtain a budgetary quote, we will needto know the body, seal and trim materials and port connections. The more information provided, the more accurate the quote will be. For the full requirements see the valve model's datasheet. Our applications engineers would be happy to help you throught this process, or you can use the filters and flow calculator on our thermostatic valve specification page. | |

| What information do I need to specify an actuated control valve (Model G)? | |

| In addition to the information required for the thermostatic temperature control valve above, we will need to receive requirements for the mode of actuation (refer to Mode of Actuation FAQ), and actuation of the valve: electric or pneumatic. For electric actuation we will need to know the power available (115 or 230VAC) and the control signal: main power switched relays or an analog control signal (4-20mA, 1-5VDC, etc.) For the full requirements see the valve specification datasheet found on the Model G product page. | |

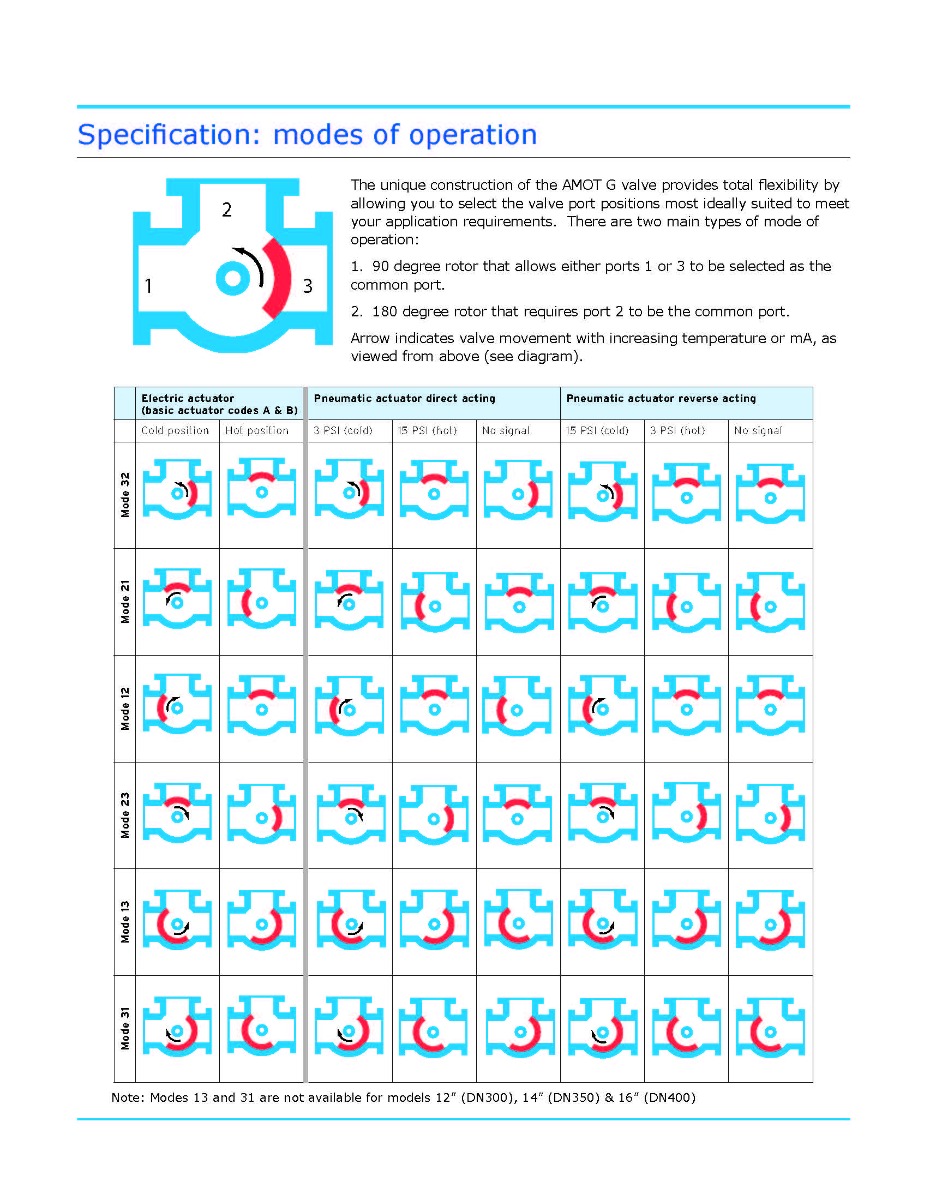

| How do I select the correct mode to configure my Model G valve? | |

| The mode on the G valve is two valve port numbers defining the operation of the valve. The valve ports are numbered 1,2, & 3 clockwise when viewed from the actuator. The first number of the mode is which port will be blocked by the rotor when the process is cold. The second number is which port will be blocked by the rotor when the process is hot. So, Mode 32 will block port 3 in cold position and port 2 in hot position. The easiest way to think of it is the 1st number is the port connected to the cooler piping. The 2nd number is the port connected to the bypass piping. Remember the port numbers in the diagram are the view of the valve from the actuator (illustration below). | |

|

|

January 11, 2022 377 view(s)