For large marine shipping vessels, bunker fuel is an important ingredient for proper machinery operation. It is a combination of fuel and lube oils stored on the ship and typically used to generate heat or motion. As you’ll see in the table below, it is broken down into three grades.

| Bunker A | The most valuable, typically called marine diesel or marine gasoil |

|

Bunker B |

Low-viscosity vac resid range bunker fuel. Often mixed lighter materials to reduce viscosity to the point that it will flow without heating |

|

Bunker C |

The least valuable and most common bunker. Composed primarily of vacuum resid range material, with a high viscosity that requires heating in order to pump. Sold at several viscosity specifications, including 180 centistoke, 380 centistoke, or 460 centistoke, with 380 being the most common grade |

Currently, most of the global shipping fleet relies on diesel Bunker C fuel oil, as it is the most common and readily available. Unfortunately, this grade also carries a higher viscosity which can lead to bunker quality issues. Traditionally, vessel operators have relied on the testing of a small sample that may not be representative of the entire supply and can take many days to process. Below, we’ll take a look at how the ViscoPro 2100 provides a solution for faster sample testing and how this can help improve bunker fuel quality.

The Importance of Viscosity in Bunker Fuel

Viscosity is an important parameter when it comes to determining the quality of marine fuels. Each grade of bunker is quoted with a specific viscosity tested at 50° Celsius. Regardless of whether a load of bunker is refinery-produced or blended at a shore facility, it is expected to be within a few centistokes (cSt) of its specification. Bunker loads can vary considerably from specification and are seldom homogeneous. The causes of off-spec bunkers vary from human error and corruption to instability of blend inherent in the original product. In many cases, the supplier is as much a victim of the system as the end-user.

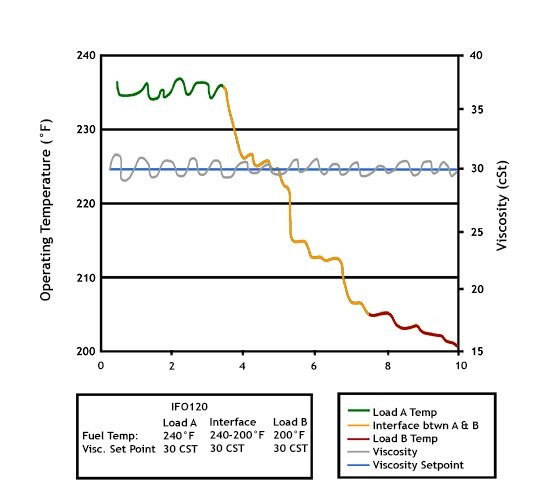

Varying grades of bunkers form layers when stored in the same storage tank. As a result, to maintain a viscosity set point, fuel oil combustion control systems must react to drastic changes of bunker viscosity when an interface between varying bunkers meets the fuel oil pump suction. The graph below illustrates a considerable change of viscosity between layers of IF0120 referred to in the graph as loads “A" and "B". The change in viscosity required a reduction of fuel temperature from 240°F to 200°F to maintain the viscosity set point of 30 cSt. Consider what would happen if the operator relied solely on a theoretical temperature set point derived from typical fuel combustion curves. Burner tips would foul more frequently, and emissions would be adversely affected.

Our Solution for Bunker Fuel Monitoring

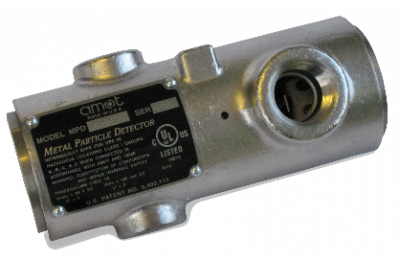

AMOT offers a solution for real-time monitoring of marine bunkers. The bunker-monitoring version of the VISCOPro 2100 uses an in-line sensor and microprocessor technology to provide real-time viscosity data during bunkering operations. As seen in the video below, the unique oscillating piston makes our viscometers extremely rugged and insensitive to harsh marine conditions. With no mechanical linkages and self-cleaning capabilities, the VISCOpro 2100 has virtually no downtime. It can run for years without recalibration.

Viscosity monitoring is crucial to the reliability and performance of your vessel. Learn more about the VISCOpro 2100 and our other oil condition monitoring products or contact us today to speak to an engineer to understand which products are right for your application.