Engine Temperature Control Valves

Prepare for future challenges with dynamic temperature control

For almost 100 years, the simple wax thermostatic valve delivered a dependable solution at an incredible value for the customer, and it was adequate for most situations. However, the world has changed—dramatically. Now, engine manufacturers and operators face tough environmental standards, government regulations, and the influence of public opinion, while feeling the pressure of tightening margins and fierce global competition. The world is ready for a new temperature control solution: Dynamic Control Valves.

Dynamic temperature control allows engines to flex to different environmental and fuel conditions, bringing efficiency benefits right to your bottom line.

- Dew Point Control

Prevent condensation & corrosion by adjusting temperature to measured humidity. - Dual Fuel Compatibility

Optimize dual fuel engines that often require different temperatures for proper combustion. Future proof for new fuel types. - Emission Control

Manage NOx emissions by adjusting to run hotter at low loads, cooler at high loads. - Fuel Efficiency

Optimize combustion and fuel usage under changing conditions.

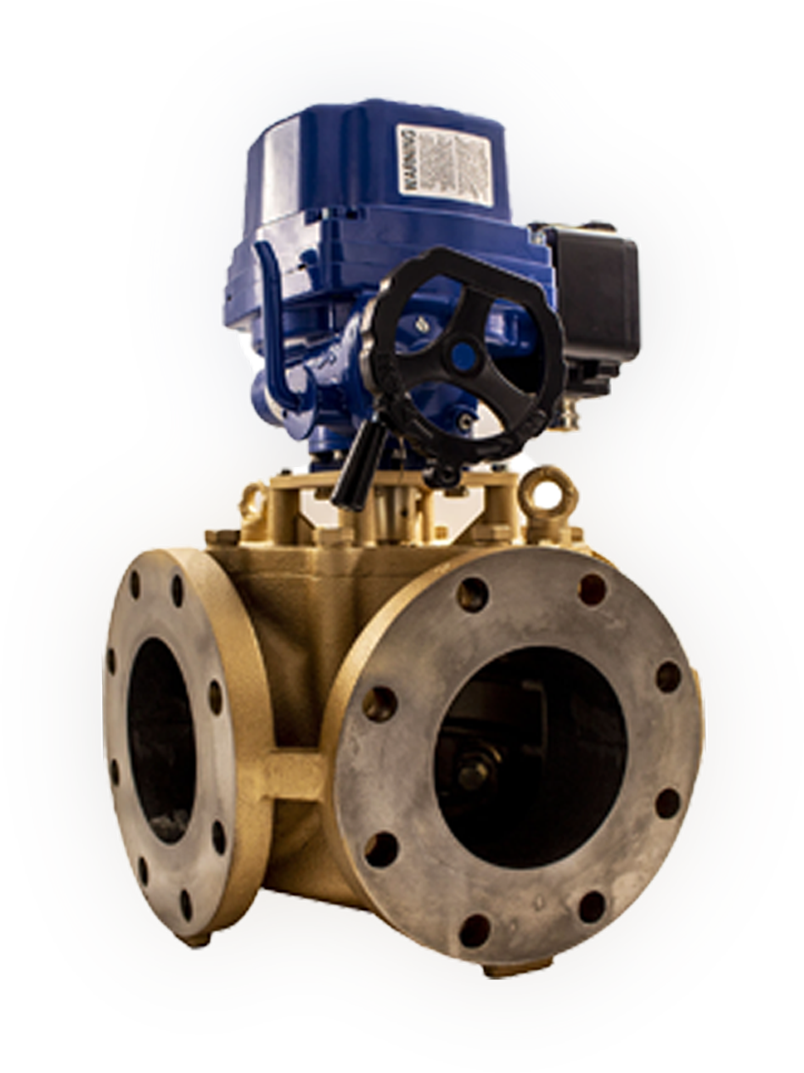

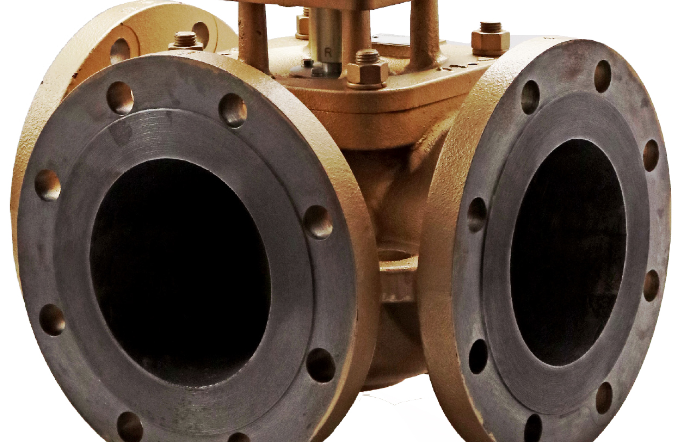

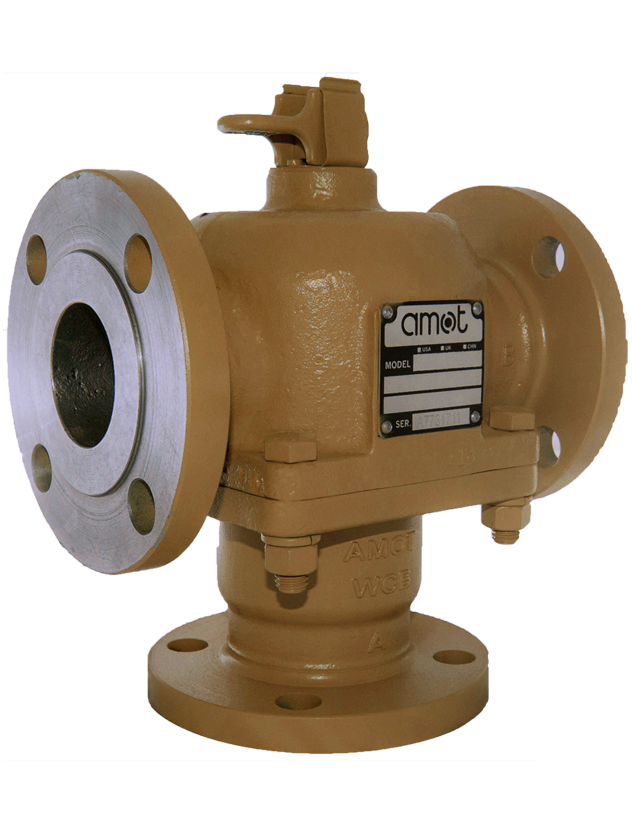

The Model G rotary valve is the optimal solution for these high horsepower engines and many more:

Rugged Thermostatic Control Valves

If you're looking for a set-and-forget solution, AMOT's rugged thermostatic control valves are self-actuated, require little maintenance, and can operate in any mounting position. Complete service kits for thermostatic valves are available with all the components needed to make maintenance quick and simple.

Diesel Engine Safety Solutions

Our diesel engine safety solutions help protect against the devastating consequences of diesel engine runaway which can occur when engines operate in hydrocarbon-rich environments. Air intake shutoff valves cut off the air supply to an engine, shutting it down if it begins to overspeed. Spark arrestors and flameproof alternators help eliminate additional risks associated with operating diesel engines in hazardous areas.

Additional Engine Products

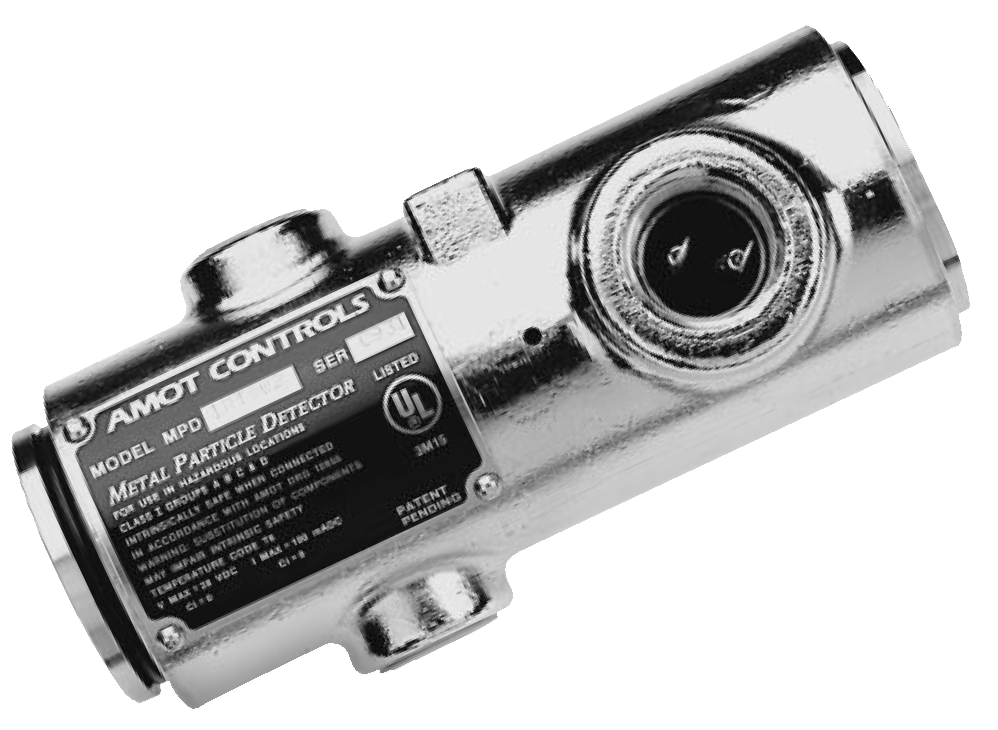

Oil Condition Monitoring

Timely detection of metal particles ensures reliable engine operation and avoids unnecessary downtime. The AMOT metal particle detector (MPD) is an in-line continuous wear debris monitor that signals the presence of metal particles in engine lubricating oils. Early warning of metal partices reduce operating costs, reduce dowtime, and prevents unneccessary repairs or parts replacement.

Sensor and Switches

Rugged, field-proven sensors and switches are an integral part of systems for steam pressure management, over-pressure protection, and vibration monitoring. Hazardous area certifications are available on certain products.

Fuel Shutoff Valves

Fuel control valves provide accurate and reliable gas control and metering for any industrial gas turbine. AMOT fuel gas valves are easily serviced in the field.

ENGINEERING UNITS

IMPERIAL METRIC