Boiler Thermostatic Mixing Valves

Protect Boiler Systems From Corrosion and Thermal Shock

When designing a non-condensing boiler system, operational problems can occur if the return water temperature is not controlled. On one hand, if the water returned to the boiler drops below 140oF (60°C), condensation of the flue gas occurs. This, in turn, causes corrosion on the copper fins of the boiler. Conversely, if the temperature of the returned water is too hot, it can lead to thermal shock, a condition where a sudden change in temperature causes rapid and uneven expansion and contraction of the boiler’s structure.

AMOT Thermostatic Mixing Valves

An AMOT 3-way thermostatic mixing valve is the simple, reliable answer to controlling return water temperatures and protecting a non-condensing boiler. AMOT offers valves in low-lead bronze, bronze, cast iron, and other body materials to meet different heating system needs.

AMOT thermostatic valves offer:

- Serviceable, factory pre-set temperature elements

- Low maintenance, mechanical operation

- Threaded or bolted flange options

- Rugged, durable construction

How Thermostatic Mixing Valves Work

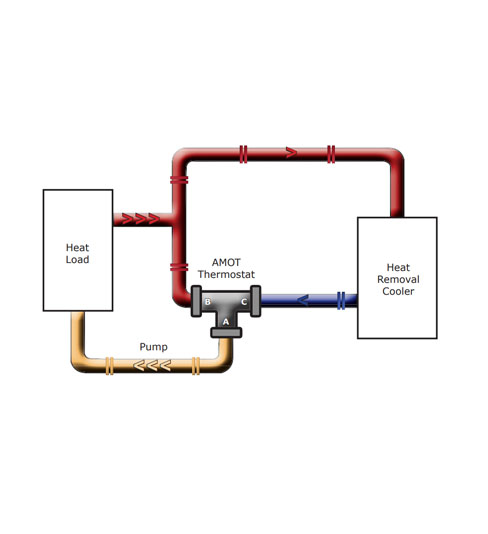

Hot water from the boiler enters port B and cooler water from the system enters port C. Port A is the temperature sensing port and will mix the hot and cool fluids to maintain the desired return water temperature.

Use our filter selection tool to help select the right thermostatic mixing valve for your application.

ENGINEERING UNITS

IMPERIAL METRIC