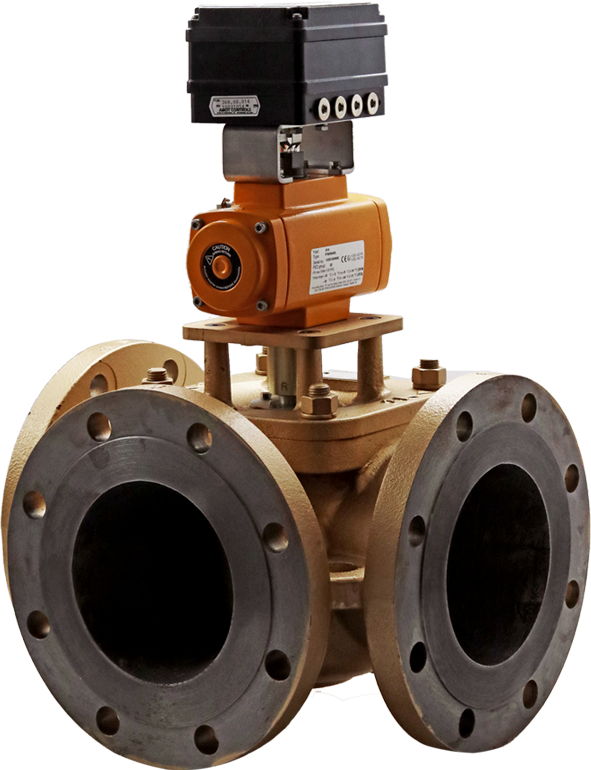

Compressor Lube Oil Temperature Control Valve

Integral Gas Compressors

Gas compressor stations are an important part of the pipeline network that moves gas from production sites to the end user. Many of these integral gas compressors have been in operation for decades and can benefit from the pneumatically-actuated 3-way Model G rotary valve. The robust Model G valve helps modernize the engine's performance and adjust to a station's ever-changing demands. They offer remote temperature sensing and quick reaction to temperature changes to improve engine reliability, decrease warm-up time, and ensure consistent temperature control.

Complete kits make the G Valve a fast, simple, drop-in replacement without incurring the cost of new pipe fabrication.

Improve Compressor Performance

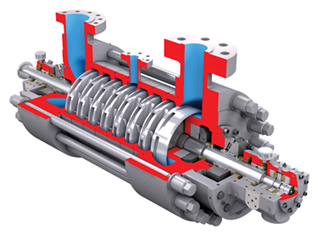

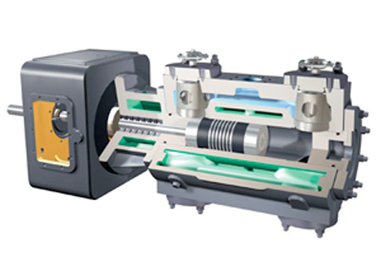

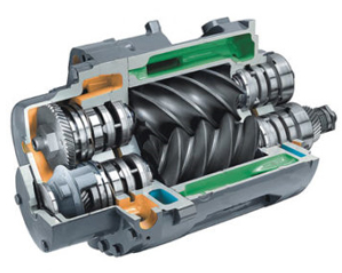

Controlling the temperate of lubrication oil is critical to compressor performance. Oil temperature must remain within a tight tolerance to maintain oil viscosity. When the temperature is too hot, oil viscosity thins and causes excessive wear of the rotary screws; if the temperature is too cold, the air forms condensation on the screws and causes them to wear out.

AMOT temperature control valves provide accurate temperature control of lubrication oil systems of all compressor styles.

Additional Compressor Products

Oil Condition Monitoring

Timely detection of metal particles ensures reliable engine operation and avoids unnecessary downtime. The AMOT metal particle detector (MPD) is an in-line continuous wear debris monitor that signals the presence of metal particles in engine lubricating oils. Early warning of metal particles reduces operating costs, reduces downtime, and prevents unnecessary repairs or parts replacement.

Bearing Temperature Detection

This bearing temperature sensor provides early warning of sudden temperature rise due to worn out bearings, broken shafts, lack of lubricant and more. View our complete line of traditional mechanical temperature detection as well as electronic sensor technology.

Sensors and Switches

Rugged, field-proven sensors and switches are an integral part of systems for steam pressure management, over-pressure protection, and vibration monitoring.

ENGINEERING UNITS

IMPERIAL METRIC

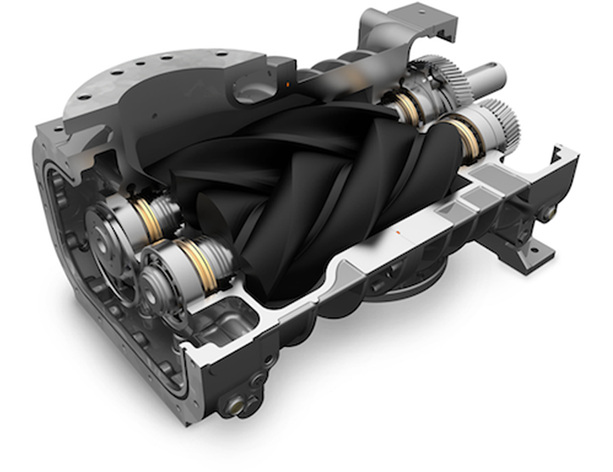

Centrifugal Compressor

Centrifugal Compressor Reciprocating Compressor

Reciprocating Compressor Screw Compressor

Screw Compressor Axial Compressor

Axial Compressor