Robust temp control for wind turbine systems

Improving Perfomance

Wind energy offers many advantages, which explains why it's one of the fastest-growing energy sources in the world. In fact, according to energy.gov, the United States’ wind power capacity has grown 15% over the last decade. Wind power is a cost-effective, clean, sustainable fuel source. However, to compete economically with traditional power generation sources, wind turbines must be efficient and reliable.

Since 1948, manufacturers have turned to AMOT solutions to improve the performance of their equipment. We continue to innovate and adapt to the world’s changing needs by moving into the renewable energy space where our suite of products improve operational performance for wind turbine manufacturers and cooling and lubrication system designers.

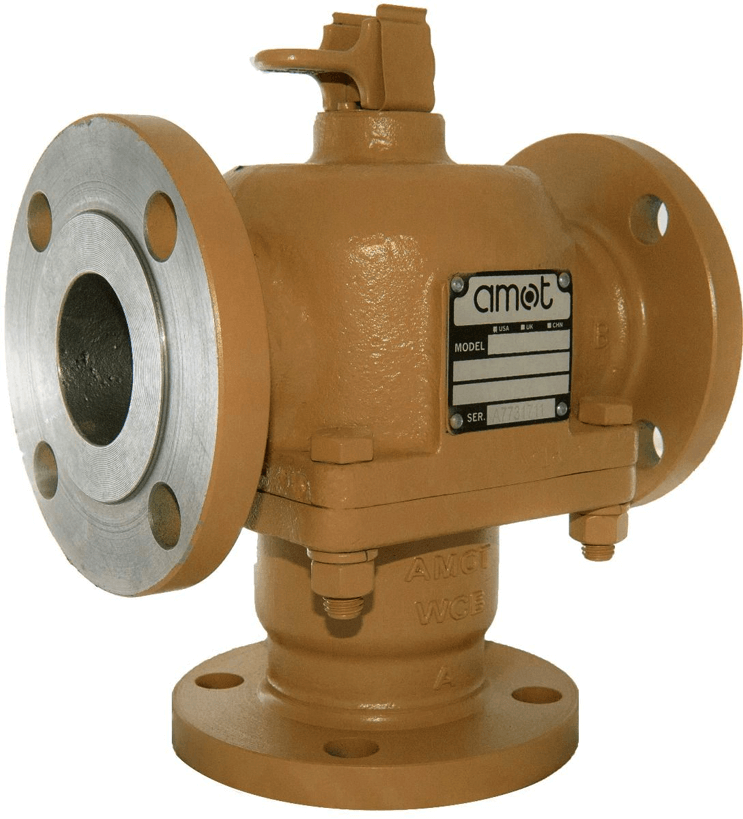

The robust, low-maintenance temperature control solution

Wind turbines are installed in rural, unpopulated areas or offshore where they have the best exposure to wind, which makes maintaining them a challenge. For this reason, OEMs and their suppliers require highly reliable, low maintenance components to ensure the equipment continues to function properly in remote, harsh environments.

AMOT 3-Way Thermostatic Valves are the workhorse of temperature control valves. For over 70 years, they have been the go-to solution for cooling and lube oil system fluid temperature control. They’re proven tough against the corrosive nature of salt water and the harsh, damaging chemicals used in industrial processes.

When a durable, low maintenance, and reliable set-and-forget temperature control solution is needed on the lube oil circuit of the gearbox within the wind turbine, you can count on an AMOT Thermostatic Valve.

Shop

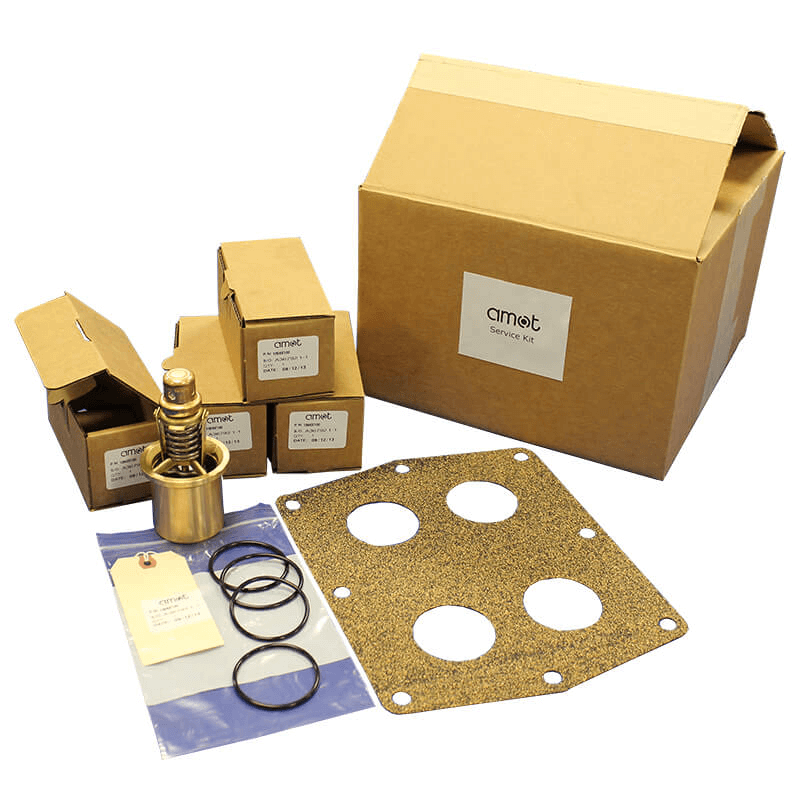

Servicing made simple

The ability of your temperature control valve to maintain a constant temperature can change over time as the internal components are exposed to chemicals and prolonged operation. AMOT recommends servicing thermostatic control valves with each regularly scheduled major equipment overhaul. Where valves are used in higher risk, sensitive, or extreme applications, we recommend more frequent inspections and replacement of seals and elements.

Our service kits contain all the components necessary, including new temperature control elements and seals, to make easy work out of valve maintenance.

ShopProtect against major equipment failure

Catastrophic failure occurs when the equipment’s moving parts are substantially damaged and cannot function properly. During repairs, mechanics often discover that abrasive particles present in the lubricating oil are the culprit. These particles can increase the oxidation rate of the oil and cause it to lose some of its anti-wear characteristics. Installing filters will minimize the number of particles prior to entering the equipment, but if the moving parts are sustaining damage, it may not be detected before a total failure occurs.

This is where the AMOT MPD2 has proven to be a valuable tool in the prevention of equipment failure due to lube oil contamination. The AMOT metal particle detector (MPD) is an in-line continuous wear debris monitor that detects the presence of metal particles in lubricating oils and alerts operators to perform maintenance before significant, costly damage occurs. It provides real-time, immediate data which allows corrective maintenance to be scheduled before expensive repairs and excessive downtime are required. Combined with a proper maintenance program, the MPD2 is a simple insurance policy against major equipment failure.

A Simple Insurance Policy to Protect Against Major Equipment Failure AMOT Products that Support Remote Monitoring of Equipment

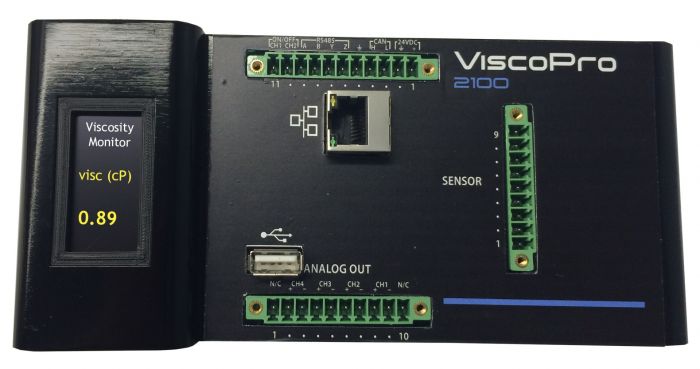

Real-time oil viscosity monitoring extends equipment life

Lube oil viscosity affects the overall efficiency of a wind turbine’s performance. If oil is too thick for the operating conditions, the machine must work harder, thus generating heat and using more energy. Over time, this will create unnecessary wear and tear on the machine. Conversely, if a lubricant is too thin, the film may not be thick enough to prevent friction. This too will create unnecessary wear and tear on the machine. Industry best practices state that gearbox oil should be sampled periodically to determine its condition and help maintain gearbox health. The VISCOpro 2100 uses the latest technology for real-time viscosity monitoring on high-vibration applications, such as wind turbine gear boxes. The VP2100 will provide an early warning of poor oil condition so you can plan preventative maintenance before extensive damage occurs.

ShopOther control products

AMOT Filterstats combine the function of 3-way temperature control and filtering simultaneously. They have a compact design and low installation cost and flexible spin-on filter manifold which allows you to use the filter size of your choice. As with other AMOT thermostatic valves, temperature and filter manifolds use fully enclosed, factory-set temperature element assemblies which provide tamper-proof operation. Filter stats are available for mixing or diverting applications.

Shop

ENGINEERING UNITS

IMPERIAL METRIC