Temperature control valves are an integral part of any heating or cooling circuit found on marine vessels. In fact, HVAC systems, lube oil loops, engine  charge air (LT), and jacket water (HT) circuits all utilize temperature control valves, and they are a big factor in an engine’s operating life. Some might argue that they are a big reason why many of the ships found on today’s waters have been in operation for over 40 years.

charge air (LT), and jacket water (HT) circuits all utilize temperature control valves, and they are a big factor in an engine’s operating life. Some might argue that they are a big reason why many of the ships found on today’s waters have been in operation for over 40 years.

Often, the temperature control valve used in these circuits is a diaphragm-operated three-way rotary control valve, or as it’s commonly known, a Leslie valve. While these valves (image, right) met operator standards 40 years ago, performance and efficiency expectations have evolved over the years.

Below we’ll look at how the AMOT Model G Valve’s modern design can provide an immediate upgrade to your current temperature control solution.

Accuracy and Adjustability

AMOT engineers designed the heavy-duty rotary Model G valve to provide the highest degree of accuracy possible. The external temperature sensing probe enables more precise, more responsive temperature control. With the ability to maintain temperatures within +/-1oF, upgrading to the Model G valve benefits sensitive applications where maintaining a constant set point is vital.

Flexibility

The Model G valve offers flexibility of use unlike any other valve on the market. First, it can operate equally well as a stand-alone valve or as part of a complete control system. This adaptability allows the customer to experience all the benefits of a Model G valve without the added cost or concern of transitioning to a new control platform.

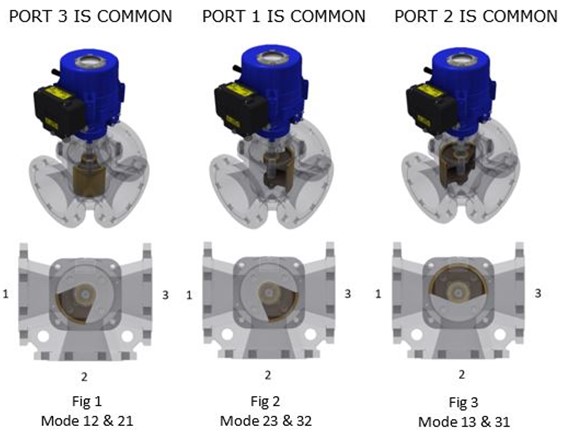

Second, while some valves have a single common port configuration, the G Valve can utilize any of its three ports as either the hot, cold, or common function. This flexible design allows it to be a drop-in solution for other actuated temperature control valves including wax-based and linear-stroke style valves.

Finally, with a range of available options, there is a Model G configuration for nearly every application and operating condition. AMOT offers several actuator types, including

- Pneumatic for hazardous environments.

- High vibration resistance for on-engine mounts and easy wiring.

- Electric actuation with a selection of voltage options.

- Right-sized actuators for better fit to valve size and installation orientation.

Reduced valve seat leakage

With the increase in fuel costs and environmental regulations, operators are constantly looking to reduce fuel consumption and improve equipment efficiency. One easy solution to this is by minimizing your temperature control valve’s seat leakage. While the Leslie valve comes standard with a maximum leakage rate of 1.5% for diverging applications and 1.8% for converging applications, the AMOT Model G Valve is available in ANSI II (0.5%) and ANSI IV (0.01%) class leakage rates. This reduced seat leakage offers several advantages including, faster warm-up times, reduced emissions, and tighter temperature control.

Higher Flowrate

While it utilizes similar rotary-style technology as Leslie RV Series Valves, the AMOT Model G Valve offers a higher flow coefficient at equivalent sizes. This allows for an increased flow rate while reducing flow resistance and pressure drop. In some instances, this can lead to cost-saving opportunities by reducing valve, piping, and pump size requirements.

| Valve Type, size (DN) | 2G | 3G | 4G | 6G | 8G | 10G | 12G | 14G | 16G |

| 50 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | |

| Kv | 82 | 207 | 323 | 729 | 1296 | 2025 | 2918 | 3972 | 5187 |

| Cv | 96 | 242 | 378 | 851 | 1513 | 2364 | 3405 | 4635 | 6053 |

Flow Coefficients:

| Size | Full Port Cv | Reduced Port Cv |

| 4" (100 mm) | 290 | 145 |

| 5" (125 mm) | 290 | 145 |

| 6" (150 mm) | 645 | 325 |

| 8" (200 mm) | 1150 | 575 |

| 10" (250 mm) | 1800 | 900 |

| 12" (300 mm) | 2590 | 1295 |

| 14" (350 mm) | 3500 | 1750 |

| 16" (400 mm) | 3500 | 1750 |

Drop-In Replacement

In addition to the advantages that the AMOT Model G Valve can bring to your application, it’s important to note that it is also a drop-in replacement for any variation of Leslie RVB, RVK, and RVD valves. Converting to the G Valve is easy because it is available in all the same sizes, body materials, working pressures, temperature ratings, and other specifications.

While sharing the characteristics above, AMOT also offers several industry and third-party certifications required for classification. This includes military, hazardous area, and IACS required certifications. A full list can be seen on the specifications tab here .

With sales and engineering support readily available around the globe, AMOT is ready to assist you with your temperature control needs. Whether replacing an existing valve or designing a new project, contact us today to learn why the AMOT Model G Valve is the best solution for your application.