Engine technicians know the importance of performing regularly scheduled preventive maintenance, and the benefits are well documented. Just Google the topic, and over 69 million results are returned. Engine manufacturers stake their reputation on making sure their products operate well and deliver results to their customers, so they usually address the topic of maintenance in their manuals and provide guidance on how often to perform checks and what parts to service.

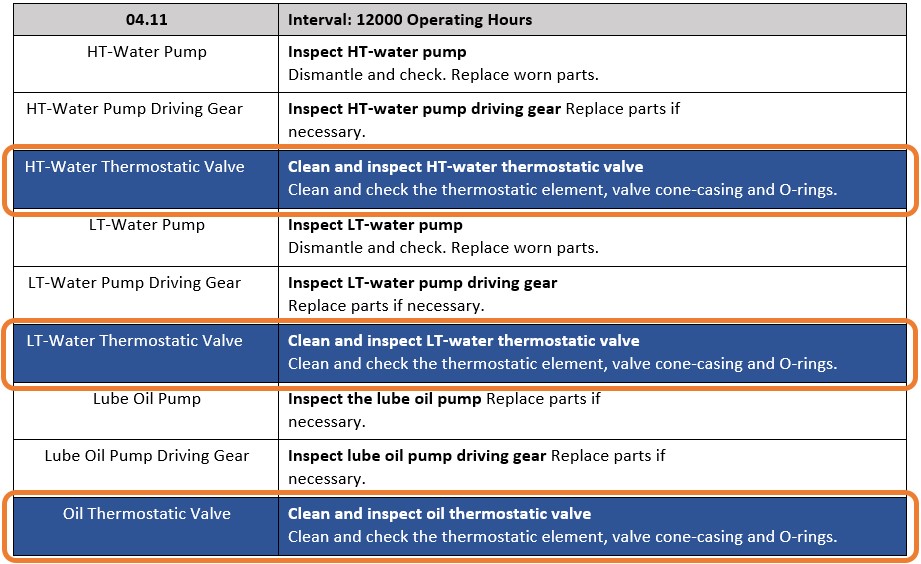

In general, engine manufacturers like Wärtsilä, Bergen, MAN, HiMSEN and others advise that cooling and lubrication systems should be serviced after every 9,000-12,000 hours of operation. In the Wärtsilä 32 engine service schedule shown below (figure 1), operators are advised to perform maintenance, which should include cleaning and inspecting the thermostatic valves that are a part of these systems, after every 12,000 hours of operation. This blog will explain how to properly clean and check the thermostatic valves to AMOT and engine OEM standards and why this is important to overall engine performance and lifespan.

Figure 1: Excerpt from Wärtsilä W32 Engine Manual

The thermostatic actuator degrades over time and failure to maintain these recommended temperatures can lead to several problems for operators, including:

- Reduced power output

- Decreased fuel efficiency

- Slow temperature response

- White smoke or excessive emissions

- Longer warm-up times

Cleaning and Inspecting

OEM Recommendations

When inspecting your engine’s cooling water and lubricating oil systems, it is important to follow the OEMs recommendations to ensure optimal performance. Most engine OEMs advise that to properly clean and inspect a thermostatic valve, you will need to remove and disassemble the valve housing, replace seal kits, and function test the elements inside the valve to ensure they are opening at the proper temperature.

To perform a function test, heat the element slowly in water and record the temperature at which the element starts opening and the temperature at which it is fully open. Then, compare these temperatures to the ones printed on the element or published in the engine manual. The half-open point is the temperature set point marked on the element.

Visually inspecting the element is equally important as function testing. As shown in the image to the right (Figure 2), typical signs that the element needs to be replaced are:

Visually inspecting the element is equally important as function testing. As shown in the image to the right (Figure 2), typical signs that the element needs to be replaced are:

- Damage or dented element cap

- Damaged or missing straps

- Damage or indention from missing/worn o-ring and sleeve

- Element slider does not fully close in cold position

- Damaged or corroded element slider

- Wear and grooves on slider from missing/worn o-ring

If the element fails the functional test or visual inspection, replace the element so that the valve can be restored to its designed performance levels.

AMOT Recommendations

While function testing elements is a good way to inspect a thermostatic valve, AMOT recommends a more proactive approach to valve maintenance.

If you plan on performing routine engine maintenance that requires disassembling and inspecting any system that utilizes a thermostatic control valve, AMOT recommends replacing the elements regardless of how it performs in a function test. If you don’t, it could be another 9,000-12,000 hours before the elements are inspected again, and unplanned maintenance may be needed to replace failing elements.

While these recommendations may seem overwhelming, AMOT makes thermostatic valve maintenance easy with ready-made service kits that contain all the components needed to maintain the valve. If you’re not sure which kit you need for your next cooling and lubricating system overhaul, contact us today.